Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

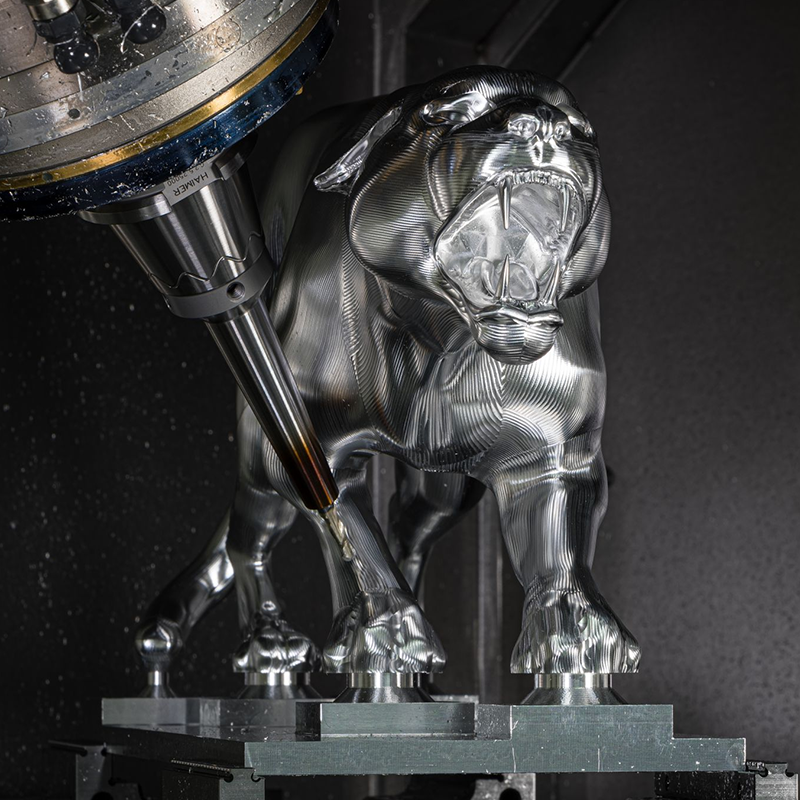

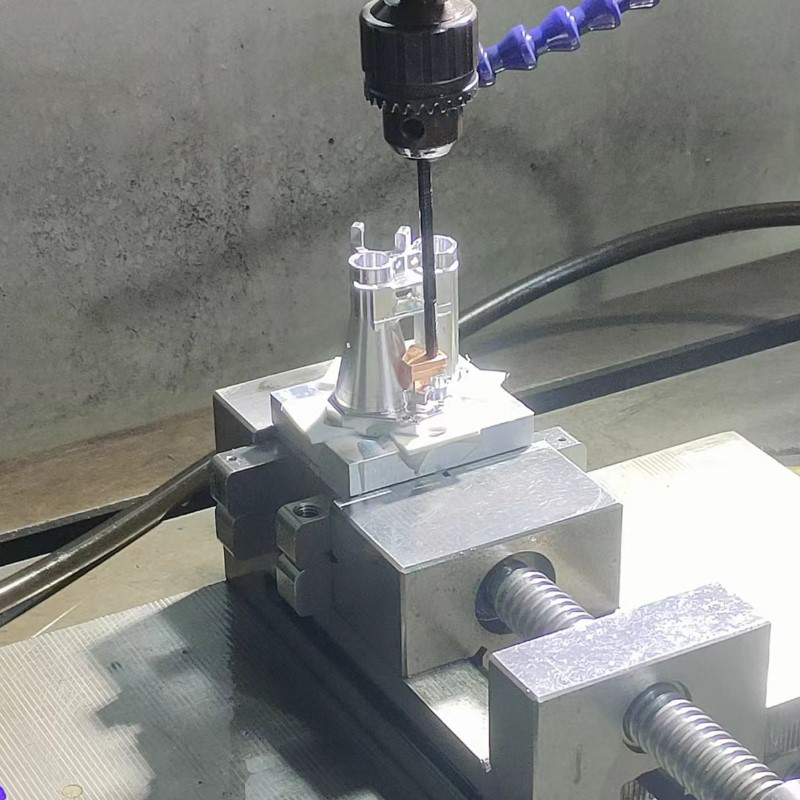

5 Axis CNC Machining Service

Elevate your machining expectations with our 5-axis CNC machining services, delivering high-precision and accurate results for intricate parts featuring extremely complex geometries. Benefit from competitive pricing and enjoy a swift turnaround for your projects.

5 Axis CNC Machining Capabilities

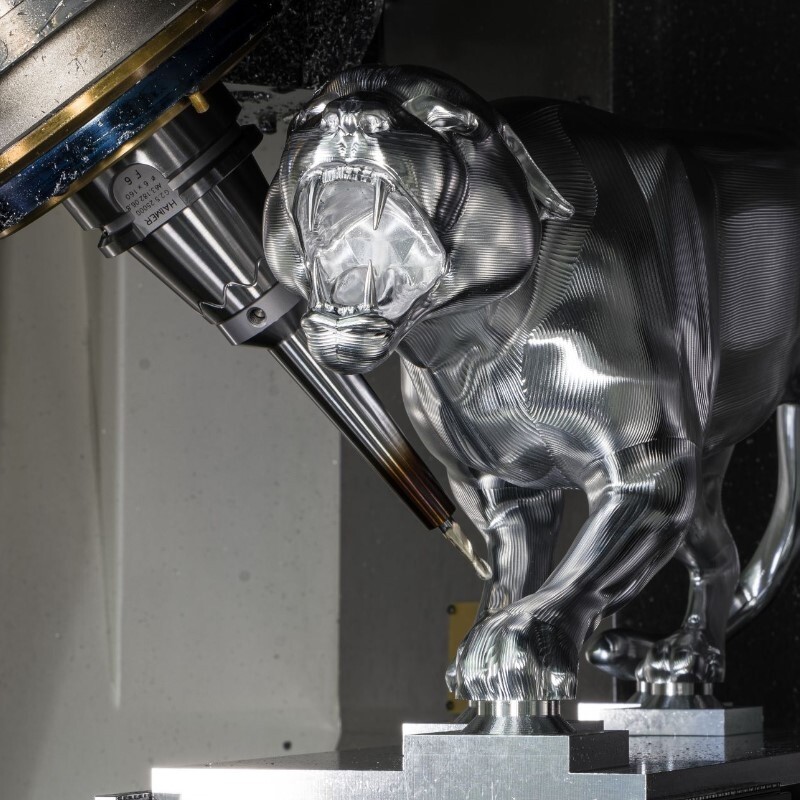

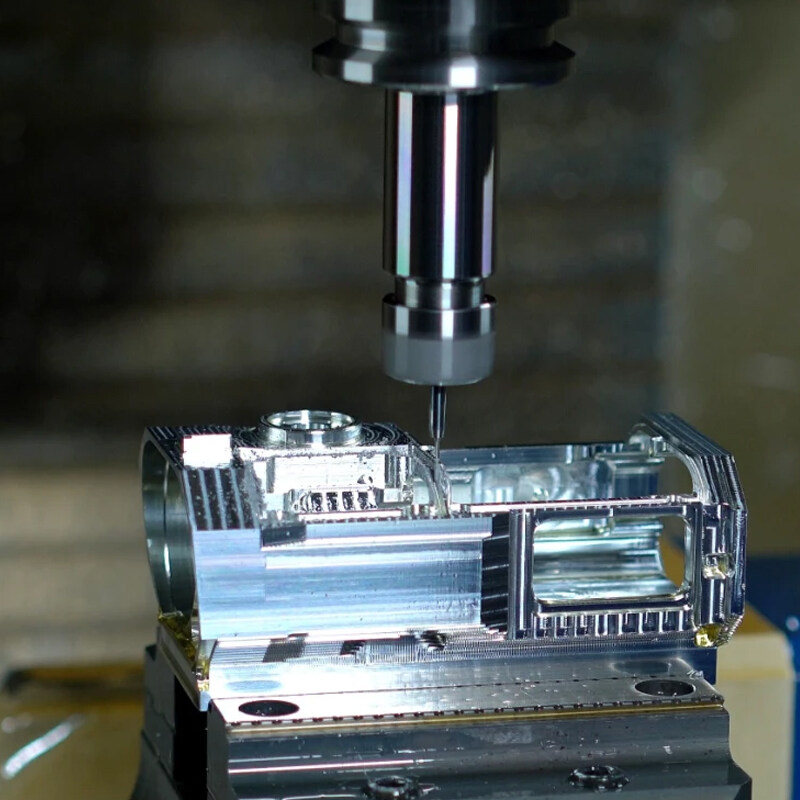

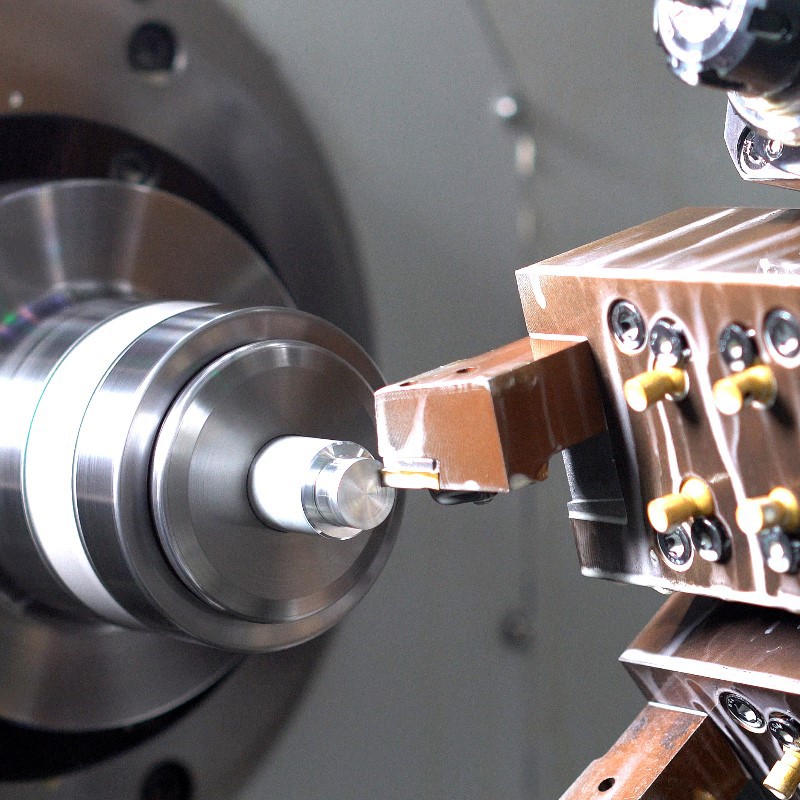

5 Axis CNC Machining is an incredibly versatile machining process that implements subtractive machining technology. Through this process, a workpiece is cut into shape using cutting tools working on five axes to deliver a final part.

Due to the increased number of axes, five-axis milling machines have greater capabilities than their three and two axes counterparts. The machines can be configured in such a way as to reduce the need for constant supervision. Efficiency and single set-up for manufactured parts are the main reasons why industries choose to implement 5 Axis CNC machining.

With an extensive range of advanced 5-axis CNC machines and various of materials, Future Parts is capable to produce precise, complex and time-sensitive components, mainly by simultaneous 5 Axis CNC Machining and 3+2 Axis CNC Machining.

Simultaneous 5 Axis CNC Machining

Fast, effective, and continuous 5-axis CNC machining with improved transitioning and surface quality. We use 5-axis machining center that can continuously adjust the movements on all five axes without stopping. Our 5-axis CNC machining has intelligent functionalities to ensure efficient continuous processes and transitions.

3+2 Axis CNC Machining

Take advantage of the optimal 3+2 axis machining technology for your unique applications. The process keeps the part fixed in a specific orientation to allow the usual 3-axis machining process. Our 3+2 axis machining uses shorter, more rigid cutting tools to offer your parts better dimensional stability. Get complex CNC machined parts with tight tolerances at lower costs and cycle time.

|

Name

|

Decsription

|

Materials

|

Color

|

Texture

|

|

|

Anodizing

|

Anodizing improves corrosion

resistance, enhancing wear

resistance and hardness, and

protecting the metal surface.

Widely used in mechanical parts,

aircraft, and automobile parts,

precision instruments, etc.

|

Aluminum

|

Clear, black, grey,

red, blue, gold.

|

Smooth,

matte finish.

|

|

|

Bead Blasting

|

Bead blasting results in parts

with a smooth surface with a matte

texture. Used mainly for visual

applications and can be followed

by other surface treatments.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A

|

Matte

|

|

|

Powder Coating

|

Bead blasting results in parts

with a smooth surface with a matte

texture. Used mainly for visual

applications and can be followed

by other surface treatments.

|

Aluminum,

Stainless Steel,

Steel

|

Black, any RAL code

or Pantone number

|

Gloss or

semi-gloss

|

|

|

Electroplating

|

Electroplating can be functional,

decorative or corrosion-related.

Many industries use the process,

including the automotive sector,

in which chrome-plating of steel

automobile parts is common.

|

Aluminum, steel,

stainless steel

|

N/A

|

Smooth, glossy

finish

|

|

|

Polishing

|

Polishing is the process of

creating a smooth and shiny

surface, either through physical

rubbing of the part or by chemical

interference. The process produces

a surface with significant

specular reflection, but in some

materials can reduce diffuse

reflection.

|

Aluminum, Brass,

Stainless Steel,

Steel

|

N/A

|

Glossy

|

|

|

Brushing

|

Brushing is a surface treatment

process in which abrasive belts

are used to draw traces on the

surface of a material, usually for

aesthetic purposes.

|

ABS, Aluminum,

Brass, Stainless

Steel, Steel

|

N/A

|

Satin

|

5 Axis CNC Machining Tolerances

For metals, Future Parts CNC machining service follows the ISO 2768-m standard, and for plastics, we follow ISO 2768-c. For custom tolerances, please mark them clearly on your drawing.

| Standards | CNC Milling | CNC Turning |

| Maximum Part Size | 4000x 1500*<600 mm 157.5x59.1x23.6 in. |

200x500 mm 7.9x19.7 in. |

| Minimum Part Size | 4x4 mm 0.1*0.1 in. |

2x2 mm 0.079*0.079 in. |

| Minimum Feature Size | φ0.50 mm φ0.00197 in. |

φ0.50 mm φ0.00197 in. |

| Standard Tolerances | Metals: ISO 2768-m Plastics: ISO 2768-c |

Metals: ISO 2768-m Plastics: ISO 2768-c |

| Linear Dimension | 士0.025 mm 士0.001 in. |

士0.025 mm 士0.001 in. |

| Hole Diameters (Not Reamed) |

士0.025 mm 士0.001 in. |

土0.025 mm 士0.001 in. |

| Shaft Diameters | 士0.025 mm 士0.001 in. |

士0.025 mm 士0.001 in. |

| Edge Condition | Sharp cormners will be removed in the form of a chamfer or radius. The size of the chamfer, or resulting radi, must be indicated on the drawing. |

|

| Threads and Tapped Holes |

Diameter: φ 1.5-5 mm, depth: 3xdiameter Diameter: φ 5 mm or more, depth: 4-6xdiameter |

Diameter: φ 1.5-5 mm, depth: 3xdiameter Diameter: φ 5 mm or more, depth: 4-6xdiameter |

| Future Parts can produce threads of any specification and size required by our customers. | ||

| Text | Minimum width of0.5 mm, depth of 0.1 mm Future Parts can use CNC engraving or laser carving to create standard text based on customers'requirements. |

Future Parts can use laser marking to create standard text for CNC turned parts. |

| Lead Time | 5 working days | 5 working days |

The Advantage of product

- High-quality finish

Cutting tools on a 5-axis CNC machine can be shorter, thus can reduce the vibration of the tool and reduce the chance of “chatter” marks and ensures a smoother surface finish.

- Faster output

Due to the high speed of 5-axis machining and increased automation, there is little need for intervention or manual processes. This is commonly known as “done in one” and “one-hit machining”.

- More complex shapes can be produced

5-axis CNC Machining can produce very complex geometries. With a single set-up, 5-axis machining can complete a piece to its exact requirements with only one fixture in most cases.

The Application of product

Our 5-axis milling services is your best bet when it comes to manufacturing complex, highly precise components for a wide range of industries. Our manufacturing capabilities allow us to accelerate the production of several components, including:

Automotive components: Engine housing, light guides, valves, engine covers, inspection jigs.

Aerospace parts: Fuselage sections, bulkheads, landing gear components.

Medical and Surgical tools: Forceps, scalpels, spacers, clamps, cutters, surgical scissors.

Military components: Submarine parts, turbine blades, engine parts, sensors.